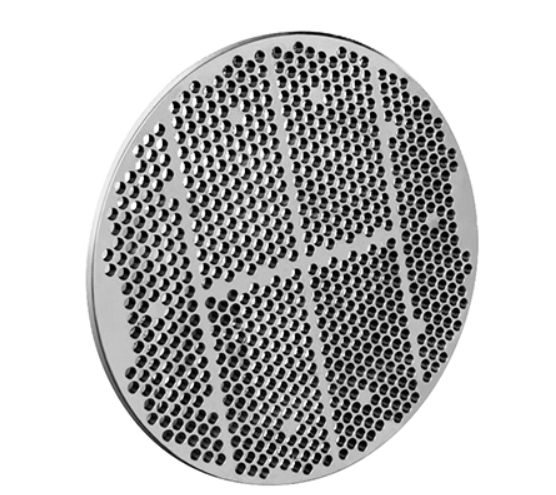

Special Custom Pipe Flanges

- Product No.

- FL_SC_FLANGES

- Details:

Steel Special Flanges are customized forged/cast metal components engineered for non-standard piping connection scenarios, designed to connect and secure pipes, valves, or equipment with unique structural, operational, or environmental requirements. Unlike standard flanges, they feature tailored configurations to adapt to complex industrial needs. Key characteristics, specifications, and technical details are as follows:

- Core Definition: Customized flanges with non-standard designs (shape, structure, or function) to address special piping connection requirements—such as irregular routing, extreme operating conditions, or unique equipment interfaces. Optimized for reliability and compatibility in scenarios where standard flanges are impractical.

- Structural Features:

- Tailored configurations – includes special shapes (square, oval, eccentric), integrated branches, irregular bolt hole patterns, or customized sealing faces (e.g., grooved, labyrinth) based on project needs;

- Forged/cast construction (forged preferred for high-pressure/critical applications) – ensures structural integrity and compatibility with special media/loads;

- Adaptable interface design – matches non-standard pipe diameters, wall thicknesses, or equipment connection points;

- Enhanced reinforcement (where required) – additional ribs or thickened hubs to withstand special loads (vibration, impact, or uneven pressure).

- Material Scope: Carbon steel (A105, Q235B), stainless steel (304L, 316L, duplex 2205/2507), alloy steel (A182 F11/F22/F91), or special alloys (Inconel, Hastelloy) – selected based on operating conditions (high temperature, ultra-low temperature, strong corrosion, or radioactive media) and compliant with ASTM, EN, JIS, or custom project standards.

- Key Specifications:

- Customizable Sizes: Non-standard DN/radius (e.g., DN1500–DN5000 large-diameter, eccentric DN50–DN300) or special length/width dimensions; compatible with standard NPS/JIS A-series where required.

- Pressure Class: PN0.1 – PN420 / Class 150 – 2500 (customizable for ultra-high pressure or vacuum systems).

- Special Design Parameters: Adaptable to temperature ranges (-269℃ – 1200℃), corrosive media (strong acid, strong alkali, chlorine-containing gas), or structural constraints (limited space, angular offset).

- Connection Methods: Welded (butt weld, fillet weld), bolted, clamped, or hybrid connections – customized based on installation environment, load requirements, and maintenance needs.

- Core Advantages:

- Customized compatibility – precisely matches non-standard piping/equipment interfaces, solving complex connection challenges;

- Durable and reliable – forged/cast structure with tailored materials withstands extreme conditions (high temperature, high pressure, corrosion, vibration);

- Easy installation – optimized design for on-site assembly, even in confined or irregular spaces;

- Versatile application – adapts to diverse industrial needs, reducing system modification costs;

- Long service life – material and structural design optimized for specific operating conditions, minimizing wear and failure risks.

- Application Scope: Widely used in oil & gas (subsea irregular pipelines, wellhead special equipment connections), petrochemical (high-temperature reactor outlets, corrosive medium pipelines), power generation (nuclear power special auxiliary systems, boiler irregular branches), marine (shipboard confined-space piping), and heavy manufacturing (customized equipment interfaces, special process pipelines) – ideal for industries requiring reliable connections in non-standard, complex, or extreme operating scenarios.